BROLIS Sensor Measurement Capabilities

Dairy farm

management

- Fat

- Protein

- Lactose

- Conductivity

- Temperature

- Urea

- Presence of blood in milk

Industrial

monitoring

- Alcohol content

- Ethanol & Methanol

- Glucose & other sugars

- Lactates

- Ammonia

- Temperature

- Color

- Turbidity

Sports performance

analysis

- Lactates

- Glucose

Healthcare,

medical & safety

- Lactates

- Glucose

- Total cholesterol

- HDL cholesterol

- LDL cholesterol

- Triglycerides

- Hematocrit

- Alcohol

- Urea

How it works?

Methods of application

BROLIS sensor may be integrated directly into industrial interface either in-line providing the fluid/substance flow-through geometry or via bypass.This configuration has the following advantages:

- Real-time composition monitoring

- Absolute levels + trend

- Direct feedback loop for process control

- Process dynamics and log option

For handheld, home use, portable off-line applications, where the sample is measured off-line. Be it a drop of blood, saliva or industrial process product/by product. A small portion of the sample is taken from the patient or industrial process, etc., and dispensed onto BROLIS sensor for spectroscopic measurement.

- Ideal for portable applications

- Quick measurement for composition

- Lower cost

- Simple use

Non-invasive option for remote monitoring. Most challenging from technology point of view but most rewarding from user experience:

- Real-time composition monitoring

- Absolute levels + trend

- No invasive procedure

- Wearables, hearables, etc.

Deeper look into technology

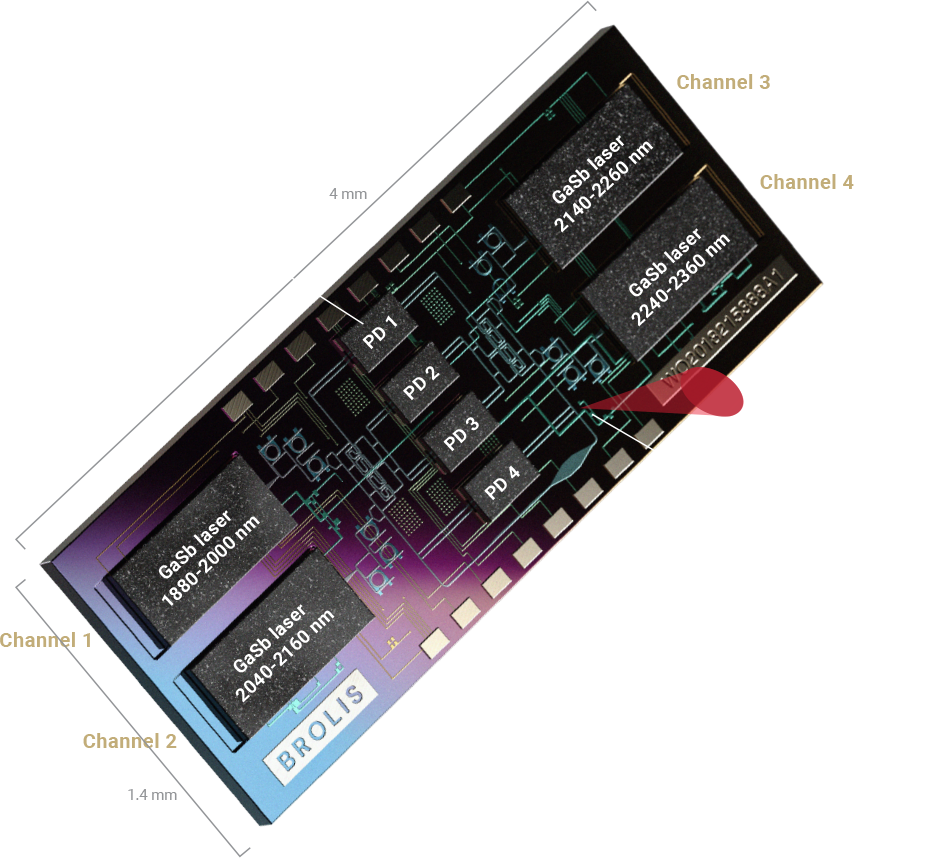

- Current BRL02 chip spectrometer 4 mm x 1.4 mm

- Key performance:

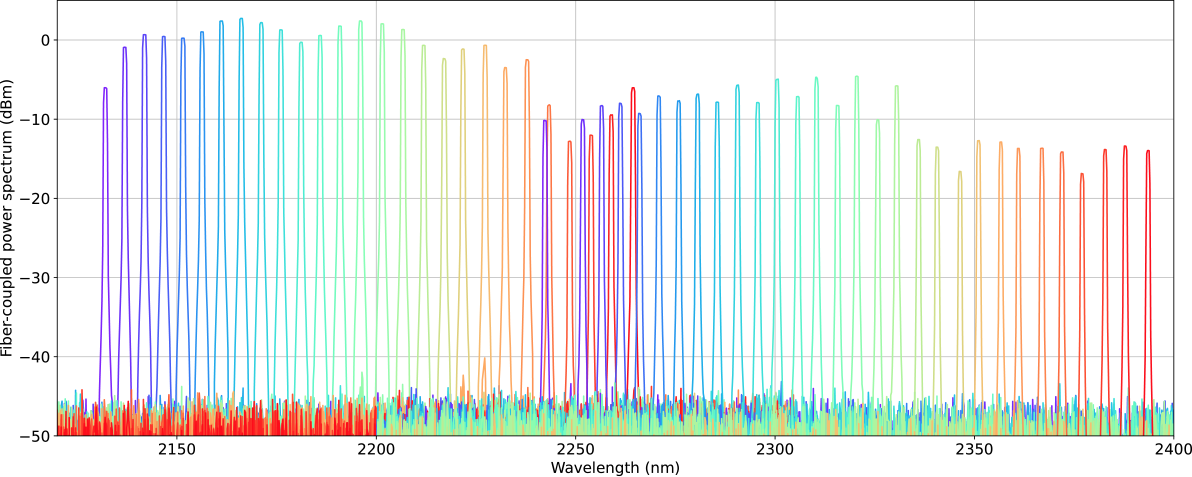

- Tuning range ~500 nm ( 125 nm/channel)

- Output power 0.2 – 0.6 mW@ 150 mA current

- 0.4 – 1.2 mW @ 300 mA current

- SMSR > 40dB

- Threshold~ 50 mA

- Wavelength stability ~ 97%

- Power stability ~ 99%

- Power consumption ~ 300 mW

Technology highlights

BROLIS’ integrated sensor is based on swept-wavelength infrared laser absorption spectroscopy. Each molecule has a unique absorption spectrum due to its various rotational-vibrational movements. This unique absorption spectrum can be used as a fingerprint for species and concentration identification.

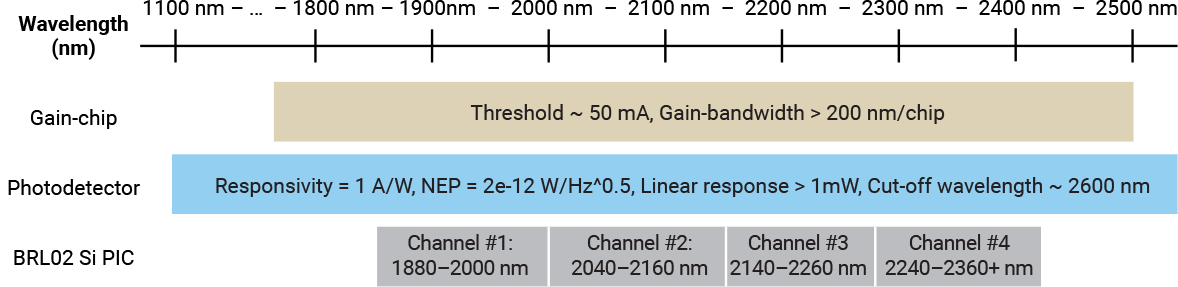

Brolis Sensor Technology owns unique GaSb/Si fully-integrated spectrometer-on-a-chip solution in the 1800 nm – 2400 nm spectral region for a wide variety of sensing applications. Our spectrometer on chip features all-in-house technology combination of:

- Extremely broadband GaSb gain-chips grown by in-house MBE

- Low noise, high yield uncooled GaSb photodetectors

- Custom Si photonic integrated circuit technology

- In-house GaSb/Si integration technology

To tackle the sensor problem, we created a technology that did not exist before. We build everything ourselves – from exotic GaSb (Gallium Antimonide) based material synthesis, to the world’s first ultra-widely swept hybrid GaSb-Si Photonics integrated laser.

The latter allowed us to create the world’s first laser-based sensors realized in a silicon photonics chip that is smaller than 5 sq. mm. All this know-how is proprietary to BROLIS and was developed purely in-house.

Patent Family of 36 patents and patent applications

are currently backing the IP behind the sensor technology